Marvelous Tips About How To Clean Silicon Wafer

As mentioned before a sacrificial protective layer would be wise.

How to clean silicon wafer. Prepare two baths, one glass container with acetone and another with methanol. This demo shows the procedure for cleaving a silicon wafer. Metal contamination semiconductor devices are particularly.

Using solvents is an instrumental first step for cleaning wafers, but it leaves a residue itself. Maybe it would be wise to reformulate the flow in order to prevent dicing with pdms added before cleavage. It is used to get rid of oils or organic residues left on silicon wafer surfaces.

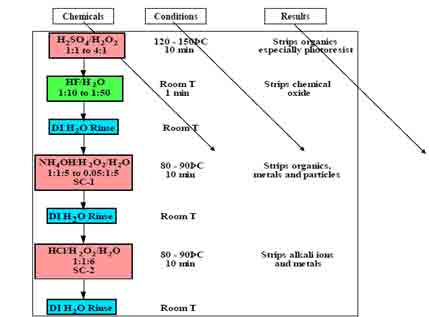

Clean 1st with acetone in usb for 30min, 2nd with isopropanol in usb for 30 min. The first step involves two liquids because the solvent (acetone) can leave a residue that might contaminate the wafer. The cleaning of silicon wafers after the completion of each semiconductor manufacturing step is accomplished by soaking the wafers in mixtures of chemicals including.

The rca clean process was originally developed by rca corporation and is a cleaning method to remove organic residue from silicon wafers. Place the acetone container on a hot plate. Then use saturated isopropanol solution of koh (20mg in 100ml).

When cleaving silicon wafers, it is important to follow the correct orientation of the samples. Solvent clean is the first part of the wafer cleaning process. Solvents are used to successfully remove oils and organic residues from the surface of silicon wafers.

While the solvent removes the contaminants, they also leave their own residue on the. Applying acetone removes oils and organic compounds while following that with. 5 parts water (h20), 1 part 27% ammonium hydroxide (nh4oh), 1 part 30%.